Can you sharpen a 3 hole punch

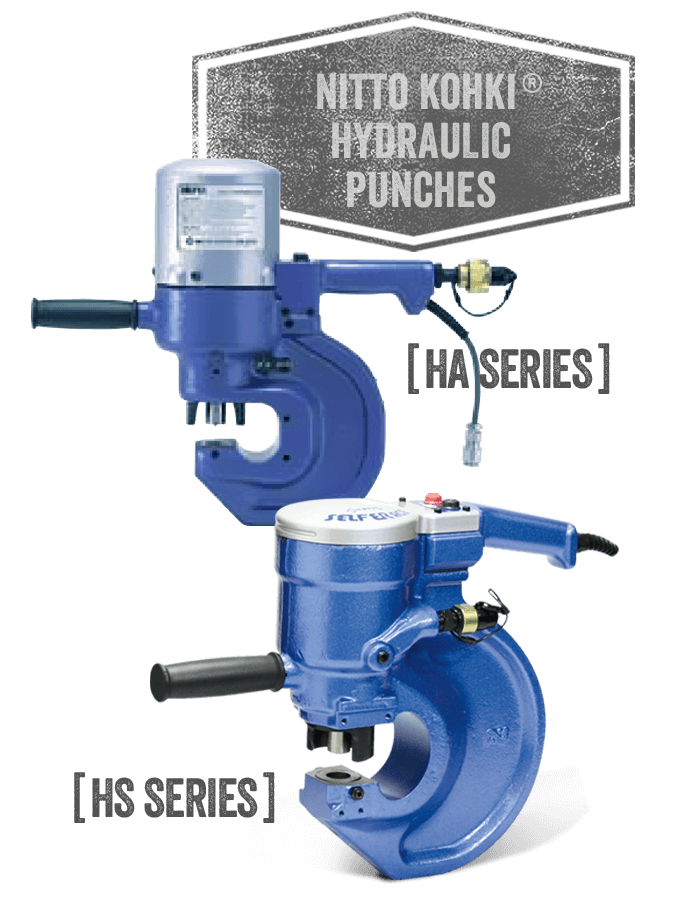

Hydraulic punches are typically controlled by hand pumps, hydraulic, gas or electrical control pumps. The hydraulic punches can also be formulated up to 10,000 psi. Hydraulic punches can be used for operations that require hand twist drills and mag drills.

They can process an infinite number of holes at a time. These processed holes are free from burrs and make them beautiful and unique.